Features of Spanco A-Series Steel Gantry Cranes

- Crane Height Adjustments: Adjusting in 6-inch increments, height adjustment kits use spring-loaded steel locking pins that automatically engage when height positioning holes are reached; adjust heights for specific lifts, uneven floors, or to move through doorways

- Adjustable Spans: Standard on aluminum cranes, adjustable spans are optional on steel cranes; adjustable spans allow the crane to be shortened for transport down narrow aisles

- Heavy-Duty Casters: Four-position, swivel-lock casters with moldon polyurethane wheels provide excellent floor protection

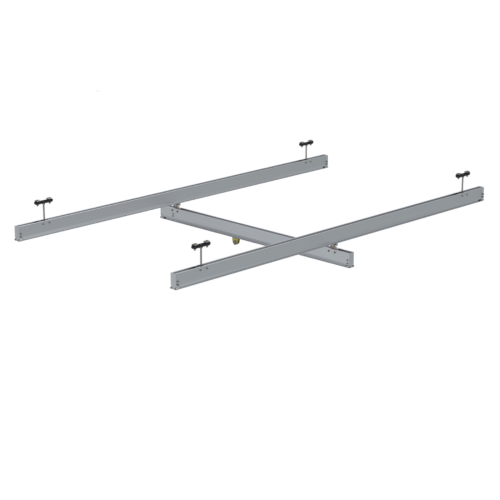

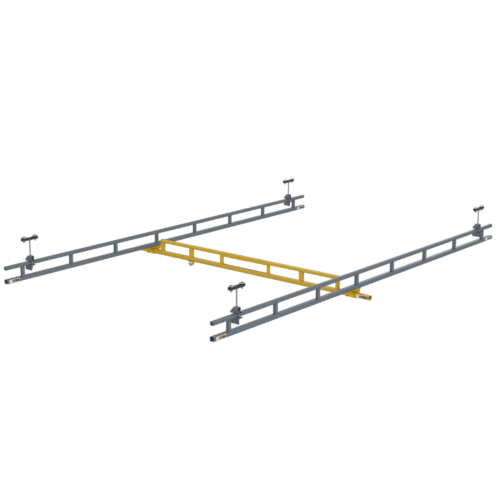

Spanco A-Series Gantry Cranes have greater clear spans because they don’t require four brace legs like our T-Series. (

NOTE: If you need the ability to adjust the crane’s

tread, see our

T-Series Gantry Cranes.)

Common Product Uses

The A-Series Gantry Crane design is one of the most popular system options available from Spanco. And, as one of the original designs from the founding of the company, has stood the test of time as a reliable material handling solution. Many different users have implemented Spanco A-Series Gantry Cranes in a wide range of industries, including:

- Manufacturing plants

- Machine shops

- Warehouses

- Construction

- Maintenance Facilities

Consolidated Sterilizer Systems: As a high-volume manufacturer of precision equipment,

Consolidated Sterilizer Systems needed material handling equipment that was both robust and precise. A complete system of Spanco cranes, including an Adjustable-Height A-Series Gantry Crane, provided the lifting flexibility and pinpoint maneuverability they required.

Bassett Industries: A large-scale metal fabrication facility in Pottstown, Pennsylvania,

Bassett Industries was in need of more lifting capacity for jobs with heavy material. They implemented a ten-ton Spanco A-Series Gantry Crane that allowed workers to lift and move large stainless steel plates.

Geisinger Healthcare System: Geisinger Healthcare System operates one of the largest emergency air transportation fleets in the US Mid-Atlantic. Their maintenance facility in Danville, Pennsylvania uses a Spanco A-Series Gantry Crane to keep their nine helicopters up to FAA standards.