Highlighted Features:

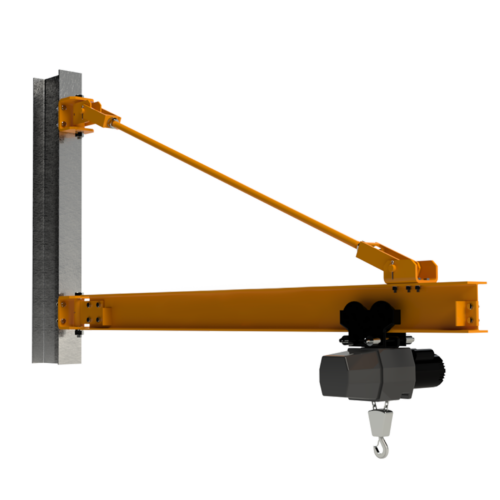

- Capacity: Supports loads up to several thousand pounds

- Range of Motion: 180-degree rotation for efficient material handling

- Construction: High-strength materials with tie-rod support for stability

- Installation: Wall-mounted design for space-saving and easy installation

- Flexibility: Ideal for various industrial applications

- Safety: Reduces manual lifting and complies with OSHA standards

- Productivity: Improves efficiency in lifting and moving loads