-

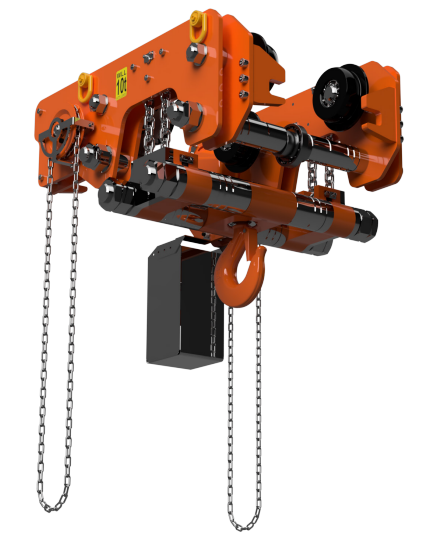

Experience the versatility and efficiency of Ultra Low Headroom Hoists, designed for demanding industrial lifting applications where space is limited. These hoists combine the functionality of a hoist and trolley, making them ideal for ultra-low headroom requirements. With load capacities ranging from 0.5 to 40 tons, these hoists are built to handle heavy lifting tasks. The corrosion-resistant load chain and hand chain ensure durability and reliable performance. The adjustable design allows for easy fitting to various beam widths, and the wheels are compatible with both I-beams and H-beams. Safety features include anti-drop plates and an overload protection safety device. Spark-resistant units are also available upon request, catering to specialized environments. Discover the power and flexibility of Ultra Low Headroom Hoists for your industrial lifting needs. With their compact design, durability, and safety features, these hoists provide efficient and reliable lifting solutions in tight spaces.

Experience the versatility and efficiency of Ultra Low Headroom Hoists, designed for demanding industrial lifting applications where space is limited. These hoists combine the functionality of a hoist and trolley, making them ideal for ultra-low headroom requirements. With load capacities ranging from 0.5 to 40 tons, these hoists are built to handle heavy lifting tasks. The corrosion-resistant load chain and hand chain ensure durability and reliable performance. The adjustable design allows for easy fitting to various beam widths, and the wheels are compatible with both I-beams and H-beams. Safety features include anti-drop plates and an overload protection safety device. Spark-resistant units are also available upon request, catering to specialized environments. Discover the power and flexibility of Ultra Low Headroom Hoists for your industrial lifting needs. With their compact design, durability, and safety features, these hoists provide efficient and reliable lifting solutions in tight spaces. -

- Ultra-low profile design

- Tight headroom

- Hoist and hand geared / push type combo

- Articulated design for special beams

- Can accommodate beams with abnormally aggressive curves

- Dual pivoting points on the trolleys allow for smooth navigation of the beam

- Corrosion-resistant packages are available

- Marine-grade finishes are available

- Spark resistant features are available

-

The SKYTAC climbing protection system allows you to climb safely up or down to any height or depth on installed vertical ladders. The guide rail with a C profile is made from 3mm wide galvanized steel and the rungs have an extra zinc layer for better protection against corrosion. To enhance the safety of users of the climbing protection system, SKYLOTEC has developed the SPEED, the only runner in the world with two redundant brake systems and a catch function that works according to speed. The principle behind SPEED is simple: the lock system is hidden in the housing and is therefore protected against unwanted access. An additional lever means that SPEED works like a pull-back runner. The runner is short and so, therefore, is the fall distance. This makes it easier to climb and also reduces injuries caused during falls. In the event of a failure of the pull-back system, whether through misuse or unfortunate circumstances, the runner can only reach a maximum pre-set speed. If this speed is exceeded, the second safety catch independently kicks in: a centrifugal brake swings the lock system out and the runner is blocked. A high number of catch in the TAC rail allow a very short fall distance. This significantly reduces the risk of injury in the event of a possible fall.

The SKYTAC climbing protection system allows you to climb safely up or down to any height or depth on installed vertical ladders. The guide rail with a C profile is made from 3mm wide galvanized steel and the rungs have an extra zinc layer for better protection against corrosion. To enhance the safety of users of the climbing protection system, SKYLOTEC has developed the SPEED, the only runner in the world with two redundant brake systems and a catch function that works according to speed. The principle behind SPEED is simple: the lock system is hidden in the housing and is therefore protected against unwanted access. An additional lever means that SPEED works like a pull-back runner. The runner is short and so, therefore, is the fall distance. This makes it easier to climb and also reduces injuries caused during falls. In the event of a failure of the pull-back system, whether through misuse or unfortunate circumstances, the runner can only reach a maximum pre-set speed. If this speed is exceeded, the second safety catch independently kicks in: a centrifugal brake swings the lock system out and the runner is blocked. A high number of catch in the TAC rail allow a very short fall distance. This significantly reduces the risk of injury in the event of a possible fall. -

Spanco Workstation Jib Cranes offer easy, ergonomic lifting and transfer of repetitive loads. These small, nimble cranes are faster than motorized jibs and are very affordable. Our workstation jibs can be permanently foundation-mounted, portable with counterweight bases, wall-mounted, or foundationless to best suit your needs:

Spanco Workstation Jib Cranes offer easy, ergonomic lifting and transfer of repetitive loads. These small, nimble cranes are faster than motorized jibs and are very affordable. Our workstation jibs can be permanently foundation-mounted, portable with counterweight bases, wall-mounted, or foundationless to best suit your needs:501 Series Wall-Mounted Workstation Jib Cranes

- 180-degree rotation

- Bolts to existing wall or column

- Bronze bearings at the pivot points ensure easy rotation

-

401 Series Wall-Mounted Articulating Jib Cranes

- Offers 360-degree rotation for outer arm and 180-degree rotation for inner arm

- Perfect for individual workstations where each worker needs complete access to one jib crane

- Outstanding headroom permits installation in tight locations and crowded shops

- Provides a clear work area with no floor obstructions and requires minimal overhead clearance for installation

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several tons

- Range of Motion: 180-degree rotation for comprehensive coverage

- Construction: Robust, high-strength steel construction

- Installation: Mounts on walls or columns to save floor space

- Versatility: Suitable for tight spaces and low headroom areas

- Safety: Adheres to OSHA regulations, reducing workplace injuries

- Efficiency: Improves load handling and workflow

-

Spanco Wall-Traveling Jib Cranes are cost-effective, custom-engineered solutions that are specifically designed to meet your production needs and building specifications. You can cover an entire series of workstations using one agile wall-traveling crane for virtually the entire length of your building.

Spanco Wall-Traveling Jib Cranes are cost-effective, custom-engineered solutions that are specifically designed to meet your production needs and building specifications. You can cover an entire series of workstations using one agile wall-traveling crane for virtually the entire length of your building.Features of Spanco Wall-Traveling Jib Cranes

- Jib boom is fabricated from standard “S” beam with vertical angle truss to reduce deflection; jib boom and truss bolt onto the back frame—no welding needed

- End trucks are constructed from channel beam frames and resist twisting; the end trucks are jig-fixed for optimal fit and travel. End trucks bolt onto the jib’s back frame

- Top-running end trucks include double-flanged crane wheels made from forged steel for long service life

- Crane drive has an electric motor with worm gear reducer

- Two-speed controls include mainline contactor, control transformer, inverter acceleration control, and fuses in NEMA 3R, 4, or 12 enclosures

- Variable frequency drives (VFDs) for multi-speed operation