- Flush-mount connection

- Drop-rod mount connection: Drops rods can be any length and require sway bracing supplied by others

- Sloped drop-rod mount connection: accommodates slopes up to 14 degrees and requires sway bracing supplied by others

- Bar joist mount connection

- Wood joist mount connection

- Custom mount connections

- Single, dual, or multiple tracks for use by one, two, or multiple workers

- Switches allow multiple users to move in different directions on the same track

- Side-mount track

- Curved track accommodates almost any degree curve

- Stainless steel track

- Intermediate bumpers can be used to limit trolley travel between the factory-installed end stops for any reason

- Any color paint, epoxy coatings, or galvanized finish

- Mylar® lip seal for heavy dust or paint overspray applications

-

-

- 10t ~ 60 ton

- Standard Hoists are Atex approved, EX II 2 GD IIC T4 (X) / EX II 2 GD IIB T4 (X) / EX II 2 GD IIC T4 (X)

- Copper platings and stainless steel components can be offered for increased spark resistance

- Rust free & replaceable Stainless steel cylinder

- 100% Duty cycle

- Ideal for working in hazardous areas (Explosive environments)

- Temperature Rated -4°F to 158°F

- Insensitive to dust and humidity

- High Grade carbon steel swivel hooks with safety latches

- Galvanized Grade 80 Load chain made to EN818 standard – 5:1 Design factor of safety

- Automatic self-adjusting multi disc brake 125% WLL.

- Tried and tested slip clutch design load limiting device set 130% WLL.

- Compact design and Lowest headroom in class.

- Anti-climb and Anti-drop devices standard.

- Pilot Pendant control with Emergency shut-off valve

- Complaint with ASME B30.16

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to 15 tons

- Power Source: Electric motors for smooth and precise movement

- Material: High-strength construction for durability

- Mobility: Smooth-rolling casters for easy movement

- Adjustability: Adjustable height and span options

- Efficiency: Improves productivity and reduces physical strain

- Versatility: Suitable for manufacturing, warehousing, and construction

- Safety: Complies with OSHA standards for safe lifting operations

-

Experience the power and reliability of Electric Motorized Trolley Chain Hoists. These hoists are designed to handle heavy loads with ease, making them a cost-effective solution for lifting applications in various settings. Crafted with durable materials and equipped with advanced features, these hoists ensure smooth operation and precise load control. The motorized trolleys ride along cast-iron guides, providing stability and minimizing friction. With drop stops, rubber bumpers, and ball-bearing-supported rollers, these hoists offer enhanced safety and reduced wear. Suitable for high-volume handling in steel warehouses, machine shops, fabricating plants, mills, and foundries, these Electric Motorized Trolley Chain Hoists deliver exceptional performance day in and day out. Upgrade your lifting operations with these high-performance Electric Motorized Trolley Chain Hoists. Perfect for a wide range of industries, these hoists provide the strength, reliability, and safety you need to tackle heavy loads efficiently.

Experience the power and reliability of Electric Motorized Trolley Chain Hoists. These hoists are designed to handle heavy loads with ease, making them a cost-effective solution for lifting applications in various settings. Crafted with durable materials and equipped with advanced features, these hoists ensure smooth operation and precise load control. The motorized trolleys ride along cast-iron guides, providing stability and minimizing friction. With drop stops, rubber bumpers, and ball-bearing-supported rollers, these hoists offer enhanced safety and reduced wear. Suitable for high-volume handling in steel warehouses, machine shops, fabricating plants, mills, and foundries, these Electric Motorized Trolley Chain Hoists deliver exceptional performance day in and day out. Upgrade your lifting operations with these high-performance Electric Motorized Trolley Chain Hoists. Perfect for a wide range of industries, these hoists provide the strength, reliability, and safety you need to tackle heavy loads efficiently. -

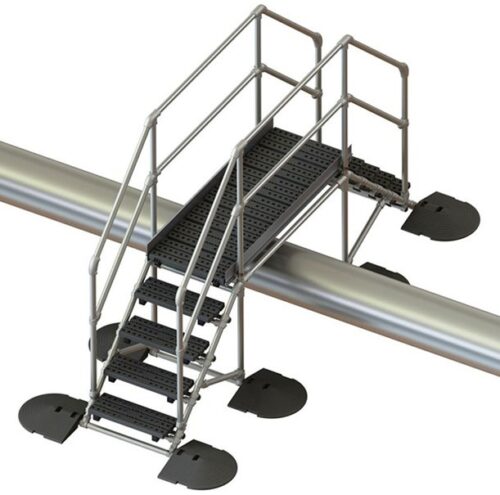

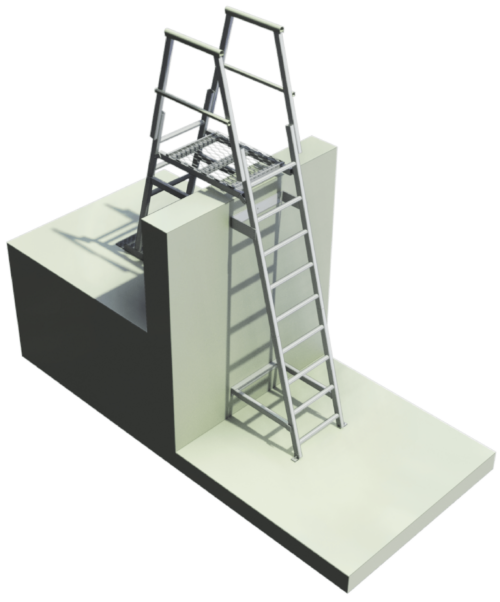

Enhance your space with our premium bolt-on aluminum railings. Crafted with precision and quality, these railings offer both functionality and aesthetic appeal. Designed for easy installation, our bolt-on aluminum railings provide a seamless addition to any setting. Constructed from durable aluminum, these railings are built to withstand the test of time. The bolt-on design ensures a secure and reliable attachment, giving you peace of mind and ensuring the safety of those around you. With their sleek and modern look, our aluminum railings effortlessly complement any architectural style. Available in a variety of finishes, you can customize the railings to suit your taste and match your existing decor. Experience the perfect combination of durability, style, and ease of installation with our bolt-on aluminum railings. Upgrade your space and create a stunning environment that will impress for years to come.

Enhance your space with our premium bolt-on aluminum railings. Crafted with precision and quality, these railings offer both functionality and aesthetic appeal. Designed for easy installation, our bolt-on aluminum railings provide a seamless addition to any setting. Constructed from durable aluminum, these railings are built to withstand the test of time. The bolt-on design ensures a secure and reliable attachment, giving you peace of mind and ensuring the safety of those around you. With their sleek and modern look, our aluminum railings effortlessly complement any architectural style. Available in a variety of finishes, you can customize the railings to suit your taste and match your existing decor. Experience the perfect combination of durability, style, and ease of installation with our bolt-on aluminum railings. Upgrade your space and create a stunning environment that will impress for years to come. -

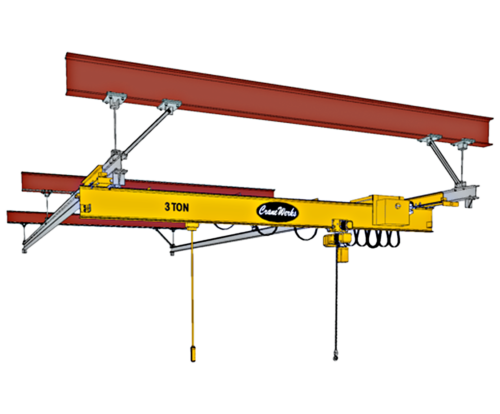

Overhead bridge cranes are permanently installed cranes within a facility that are used to lift and move material from one location to another in a safe and efficient manner. The bridge crane provides lift coverage within its full dimensional envelope which typically prevents the need for multiple lifting devices or multiple transfers. Overhead bridge cranes are typically designed and manufactured per application so that they can meet the exact needs of the user and fit within the facility’s dimensional parameters.

Overhead bridge cranes are permanently installed cranes within a facility that are used to lift and move material from one location to another in a safe and efficient manner. The bridge crane provides lift coverage within its full dimensional envelope which typically prevents the need for multiple lifting devices or multiple transfers. Overhead bridge cranes are typically designed and manufactured per application so that they can meet the exact needs of the user and fit within the facility’s dimensional parameters. -

The Parapet Clamp Guardrail system offers both affordability and simplicity in its design and operation. While it is frequently underestimated, guardrails and warning lines play a crucial role in ensuring worker safety by effectively obstructing their exposure to potential fall hazards. With the Parapet Clamp Guardrail, each clamp is thoughtfully equipped with a matching guardrail post that seamlessly accommodates 2×4” boards. This compatibility enhances the system's versatility and ease of use. It allows for a secure and reliable installation, providing a sturdy barrier for workers at height. The innovative design of the guardrail post and clamp combination facilitates the swift and efficient assembly of the entire system. What sets the Parapet Clamp Guardrail apart is its convenience during installation. Thanks to its user-friendly design, one person can easily set up the system, often without the need for additional assistance, ladders, or scaffolding. This not only saves time but also eliminates the hassle associated with acquiring and maneuvering such equipment. The simplicity of the installation process ensures that workers can swiftly implement the necessary fall protection measures, enhancing their productivity and promoting a safe working environment.

The Parapet Clamp Guardrail system offers both affordability and simplicity in its design and operation. While it is frequently underestimated, guardrails and warning lines play a crucial role in ensuring worker safety by effectively obstructing their exposure to potential fall hazards. With the Parapet Clamp Guardrail, each clamp is thoughtfully equipped with a matching guardrail post that seamlessly accommodates 2×4” boards. This compatibility enhances the system's versatility and ease of use. It allows for a secure and reliable installation, providing a sturdy barrier for workers at height. The innovative design of the guardrail post and clamp combination facilitates the swift and efficient assembly of the entire system. What sets the Parapet Clamp Guardrail apart is its convenience during installation. Thanks to its user-friendly design, one person can easily set up the system, often without the need for additional assistance, ladders, or scaffolding. This not only saves time but also eliminates the hassle associated with acquiring and maneuvering such equipment. The simplicity of the installation process ensures that workers can swiftly implement the necessary fall protection measures, enhancing their productivity and promoting a safe working environment. -

Highlighted Features:

Highlighted Features:- Capacity: Lifts up to 2,000 lbs depending on the model.

- Adjustability: Arm adjusts to multiple angles for precise lifting.

- Portability: Easily transported to various job sites for versatile use.

- Rotation: 360-degree rotation for full load maneuverability.

- Material: Corrosion-resistant materials for harsh environments.

- Mounting: Quick base installation options for truck beds, docks, or floors.

- Safety: Reduces manual strain and adheres to OSHA lifting regulations.

-

402 Series Portable Base Articulating Jib Cranes

- Easy installation at nearly any location

- Offers 360-degree rotation for inner and outer arms

- Anchor bolts are used to secure the baseplate to a counterweight base for portability and stability under load

- The pipe mast’s connection to the hexagonal baseplate is reinforced with six equally spaced gussets

-

Highlighted Features:

Highlighted Features:- Capacity: Supports loads up to several thousand pounds

- Mobility: Equipped with a portable base for easy relocation

- Construction: Made from high-strength materials for durability

- Versatility: Suitable for various industrial applications

- Flexibility: Adjustable height and reach for precise load handling

- Safety: Complies with OSHA standards to ensure a safe work environment

- Productivity: Improves efficiency with smooth, precise load handling

-

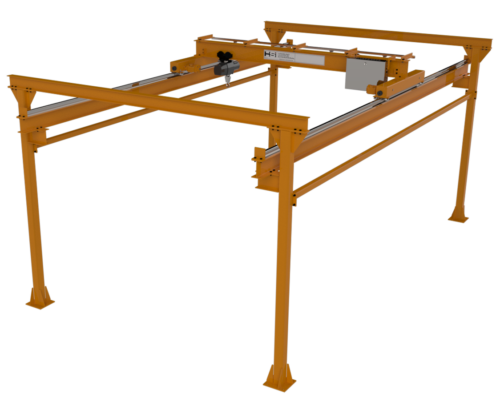

- Custom heights, spans, cantilever design, and support structures

- Single, dual, or multiple tracks for use by one, two, or multiple users

- Intermediate bumpers can be used to limit trolley travel between the factory-installed end stops for any reason

- Twin bays (tracks on both sides of posts)

- Any color paint, epoxy coatings, or galvanized finish

- Mylar® lip seal for heavy dust or paint overspray applications

-

The power drive kit includes: Two drives with drive wheels and sprockets; chains; two gear reducers; two single-speed, 230/460V, three-phase, TEFC motors; solid state, adjustable “soft start”; and two idler assemblies. Standard travel speed is 50 FPM.

The power drive kit includes: Two drives with drive wheels and sprockets; chains; two gear reducers; two single-speed, 230/460V, three-phase, TEFC motors; solid state, adjustable “soft start”; and two idler assemblies. Standard travel speed is 50 FPM.- V-Groove Track Drives: Two motors drive rigid steel V-groove wheels along a fixed path

- Guide Angle Drives: Ideal for installations where the gantry runs along a wall, two motors drive polyurethane wheels that are guided on one side by a guide angle (locally sourced). The guide angle lags into the floor, typically at the base of a wall. The kit includes guide rollers on one drive and one idler assembly. Both drives and idlers come with polyurethane bumpers.

- Truly Trackless (Aligning) Drives: Ideal when you need to keep your shop floor clear of any tracks or angle guides, a selector switch on the control pendant selectively turns each motor on and off to guide the gantry along

-

- Connecting a power drill directly to the drive mechanism

- Connecting a power drill to the flexible drive shaft

- Using the hand crank directly to the drive mechanism

- Connecting the hand crank handle to the flexible drive shaft

- Standard product is attached with powershaft 5ft, a bit and a handle

- Lifting speed meets the below specifications when r.p.m. of cordless driver drill is 1,300.

- Please apply 15.6V cordless driver drill to EHMF-38.

- Do not use electric or pneumatic impact driver.